| LACROIX’s last Investor Day was held in May 2023 at the Symbiose plant, inaugurated in September 2022. It was an opportunity for thirty of our investors and shareholders to (re)visit Electronics activity newest production site.

The day’s activities ranged from the discovery of the plant operations to discussions with Vincent Bedouin, LACROIX CEO, about the Group ambitions in a market that offers a wide range of opportunies. |

|

The electronics market

The Electronics activity, the Group’s industrial backbone, positions LACROIX as a major player in the design and manufacture of embedded electronic systems and industrial IoT.

Ranked in the world’s Top 50 EMS (Electronic Manufacturing Services), LACROIX designs, industrializes and produces electronics for the automotive, industrial, home and building, avionics and defense, and healthcare markets.

Key figures :

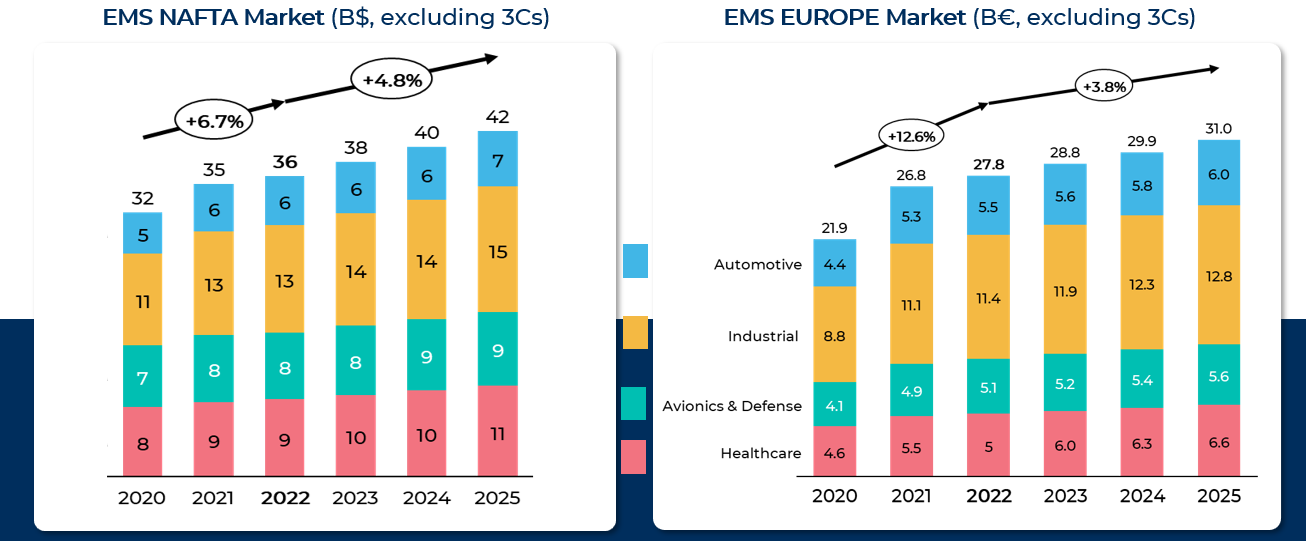

- Of a $1,500 billion electronics market, 42% is outsourced to EMS companies.

- Excluding the 3Cs (Computer, Communication, Consumer), the worldwide EMS market for professional electronics is worth $113 billion.

- Of this segment, $64 billion, or 4% of the total electronics assembly market, will be concentrated in 2022 in EMEA and NAFTA, the two areas addressed by LACROIX.

All forecasts are made in constant prices and excludes recent inflation.

A growing market

Two major trends are driving this growth in the professional electronics sector: the rise of IoT and sensors and the development of electric and hydrogen mobility.

These positive changes add up to the strategic and economic challenges of reindustrialization and relocation, both in Europe and North America (NAFTA), fuelling a global dynamic of industrial transformation:

Awareness & resilience

|

Economic Interest

|

Environmental challenges

|

Visit of Symbiose plant

The visit began at the component storage tower, a state-of-the-art facility that combines automation and digitalization to efficiently manage large quantities of electronic parts. This tower makes a significant contribution to optimizing production and improving productivity at the Symbiose plant.

The assembly shop |

The robustification stage |

The training center |

|||

|

|

|

|||

| The assembly workshop, equipped with automatic component insertion, simplifies and speeds up the assembly process. | The robustification stage, which takes place when the cards are varnished, strenghtens their durability and resistance. | The training center has already provided 4,000 hours of training to prepare employees for tomorrow’s challenges. |

The automated warehouse

The automated warehouse has a storage capacity of 650 cubic meters. Inside, 6,720 bins and 7,000 crates facilitate the storage of electronic components and finished products.

The result is a 33% productivity gain.

This automated warehouse makes a significant contribution to speeding up logistics processes and improving supply chain efficiency.

Check out our smart blog.

-

Explained

Computer Vision: turning images into information

LACROIX Impulse

-

Expert's take

What is EV Charging?

LACROIX

-

Explained

Electric mobility and green hydrogen for a sustainable future

LACROIX

-

Explained

Digital technology to power the energy revolution

LACROIX

-

Explained

Connected devices: are they of any help in dealing with societal issues?

LACROIX

-

Explained

How to structure innovation thanks to the ISO 56000 standard?

LACROIX