18 December 2023

LACROIX

4 minutes de lecture

Faced with the challenges of reducing energy consumption and decarbonizing our industries, we need to develop virtuous models that are in line with climate change and the development objectives of our industries.

Enhance the efficiency and sobriety of the entire industrial chain

Industry 4.0: an ally in the ecological transition of industrial sectors

Over the past thirty years, the manufacturing industry has reduced its direct greenhouse gas emissions by 45% in France (source: French National Industry Council).

While this result is encouraging, we need to continue transforming our production methods to run our sustainable operations.

To achieve this, we can make changes at all our production sites, starting by implementing less energy-intensive and more efficient manufacturing and industrialization processes.

By integrating automation and digitalization into our processes, we can adjust production to demand, thus optimizing our energy consumption and improving machine performance over the long term.

Ultimately, thanks to improved industrial performance, we can reduce our carbon footprint and thus reconcile both our development and decarbonization objectives.

The integration of these new processes is an important lever for boosting the sobriety of our industrial sectors with efficiency and speed.

For example, our Symbiose 4.0 plant, due to open in September 2022 in Beaupréau-en-Mauges, generates 2.5 times fewer greenhouse gas emissions per m2 than our previous plant in Saint-Pierre Montlimard.

Holistically rethinking our industrial processes to reduce our carbon footprint

Integrating technology at the heart of production processes is crucial to the sobriety and efficiency of our industries.

However, for a sustainable reduction in greenhouse gas emissions, manufacturers need to take action across their entire production chain, from purchasing policy to the environmental impacts of production sites (water, renewable energies, raw materials, mobility, etc.) in order to be truly part of an energy transition process.

At LACROIX, we are committed to conducting our operations in a sustainable manner through 3 actions:

- Reduce our greenhouse gas emissions

- Improve our purchasing practices

- Limit other environmental impacts

Thanks to these actions, we are currently working closely with recognized organizations (SBTi, ADEME, CDP, etc.) to achieve the Group’s objectives for 2025 and 2030.

Discover LACROIX’s objectives to run our sustainable operations

Industrial sectors have the resources needed to create more sober and sustainable models, provided they restructure their production chains as a whole.

These technological changes will only have an impact if the products manufactured by the industries are useful and eco-designed.

Direct business towards useful, eco-designed products with a positive impact

Useful, eco-designed products that meet real needs in the field

To make our industrial model more sober and sustainable, we are convinced that we must design and manufacture useful products that meet our customers’ real needs.

Because we believe in the power of the collective, we involve all our stakeholders in the creation and development of our products.

As an IoT solutions provider and technology equipment supplier for critical applications, we design and manufacture electronic equipment and solutions for markets that are essential to the smooth running of our society.

Dialogue between LACROIX and the professionals in these sectors is therefore essential to understand the real issues in the field.

Today, 99% of LACROIX’s carbon footprint is linked to the energy consumption of our products and the purchase of raw materials.

To reduce the carbon footprint of our products as much as possible, we work on their eco-design, taking into account :

- The physical product, to consume less material, integrate recycled materials or reduce production energy consumption

- The connectivity of our connected objects, by integrating more economical data exchange protocols or reducing the amount of data stored

In this way, our products consume less energy throughout their life cycle, from production to application.

By 2025, we aim to eco-design 100% of LACROIX products.

A determination to develop our positive-impact business

The development of business with a positive impact will only be possible if manufacturers are willing to serve markets that demonstrate high added value in the service of environmental issues.

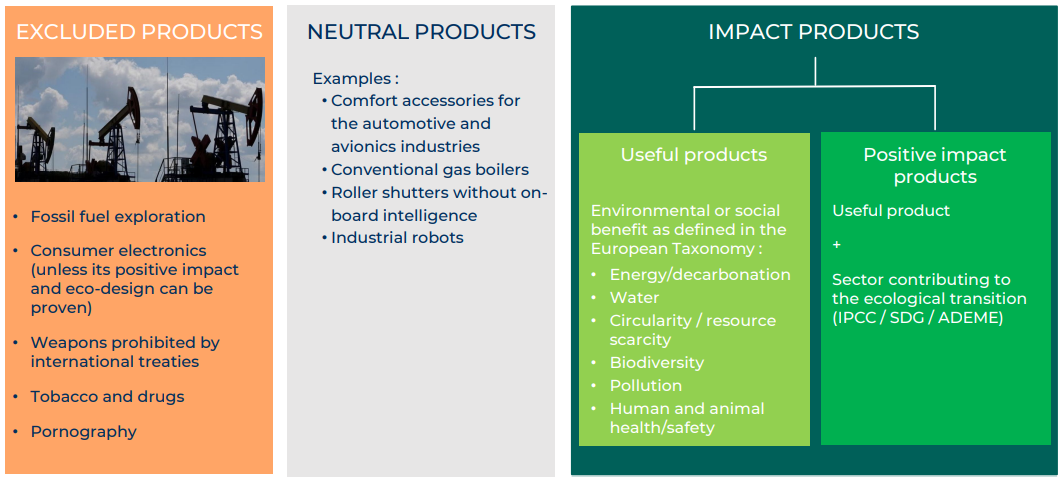

LACROIX is committed to this trajectory and has set up the LACROIX Impact Score to determine which economic business to develop:

As a result, the Group has identified 3 product categories. Our aim is now to focus on products that are either useful or have a strong positive impact.

Most of the equipment and solutions offered by our City and Environment activities have a positive impact, as they enable us to optimize and secure the management of critical infrastructures such as intelligent roads, water and energy networks.

We are therefore continuing to develop our offers and innovate to better meet the needs of our end markets.

Through the Electronics activity, certain markets will no longer be served in order to accelerate our production in high-impact markets (automotive, buildings, industry, etc.) and tomorrow’s markets such as electric mobility and hydrogen.

Our aim is for our positive-impact business to represent 80% of our sales by 2030 (compared with 60% in 2022).

To meet today’s challenges, industrial sectors need to take the turn towards decarbonization and sobriety by adopting more virtuous models.

By developing our production processes in a holistic approach, we have the opportunity to reconcile ecological transition and development objectives.

These transformations must serve a useful and eco-designed technology, because it is the positive impact that will generate the most profitable and sustainable growth.

Plus d'articles

Explained

Mobilize PowerBox: the french revolution for the energy transition

Explained

Towards a more sober and sustainable industrial model

Conversation

Q&A: LACROIX’s positive impact actions

Explained

Electric mobility and green hydrogen for a sustainable future

Explained