The first two commitments of our positive impact strategy focus on our products, aiming to maximise their positive impact and minimise their footprint.

“Run sustainable operations” concerns our sites and operations, including our purchasing.

Decarbonize our activities: a validated climate trajectory

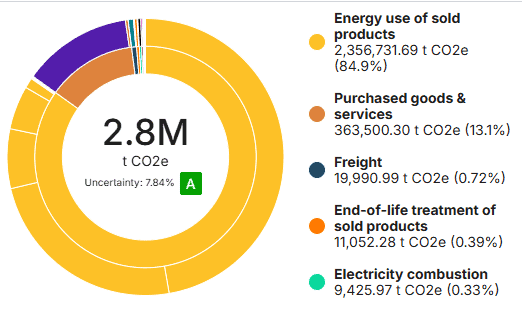

LACROIX’s carbon footprint was 2,8 Mt Co2e in 2024.

- In March 2023, we signed an agreement with the Science Based Targets Initiative (SBTi). After a year of workshops involving all Group departments, we have defined ambitious targets for reducing our greenhouse gas emissions, in line with the Paris Agreement.

- To build this low-carbon trajectory, which commits us for the next ten years, we took part in the ACT Pas à Pas program, in partnership with ADEME.

- Our near-term targets were officially validated by the Science Based Targets initiative in May 2025.

Our targets for 2033:

GHG emissions scopes 1 & 2 : -55% (vs 2023)

GHG emissions scopes 3 : -61% (vs 2023)

Reduce our environmental impact

Our Group has 14 sites, including 10 manufacturing sites and almost 82,000 m2 of buildings.

In 2024, we consumed 30.8 gWh of energy and produced more than 1,800 tonnes of waste.

To minimise these impacts, we have carried out a comprehensive environmental audit of all our manufacturing sites, focusing on energy, water, waste and raw materials.

Based on the audit, each site have set its own reduction targets.

By 2030, we are aiming for a 30% reduction in the amount of waste generated per € of revenue.

Commit to responsible purchasing

The main challenges of our Responsible Purchasing policy are Eco-design, decarbonation, logistics & packaging and social & governance issues.

As we have seen, the primary environmental and social issues associated with our operations are located in our upstream value chain, specifically, within our supplier network.

In 2024 we purchased:

- 2,200 tonnes of circuit boards

- 1,000 tonnes of plastic

- 1,235 tonnes of metal

- 1,330 tonnes of electronic components

These challenges concern the production purchases, mainly the families of electronic components, PCB and metal plastic.

Non-production purchasing mainly concern energy, buildings, information technology, vehicles, external services, small equipment and supplies. Working groups have been set up to improve our practices on green materials, packaging, logistics, etc.

LACROIX held its first CSR Suppliers’ Day with its international suppliers in October 2024.

It is now important for our suppliers and partners to be involved with us, in particular through:

- Signing the Supplier Code of Conduct

- Participation in the CSR Assessment Questionnaire

- Using the CSR Getting Started Guide

Our targets for 2025 are:

75% of our purchase volume covered by a CSR assessment

95% of purchasing volume covered by our code of conduct

Discover our Impact Report

Want to find out more?

Find out more about all our actions under the 4 pillars of our positive impact strategy.