“Design eco-efficient solutions” has two main priorities:

- Eco-designing our products

- Developing low-impact digital solutions.

In 2024, we manufactured over 72 million products.

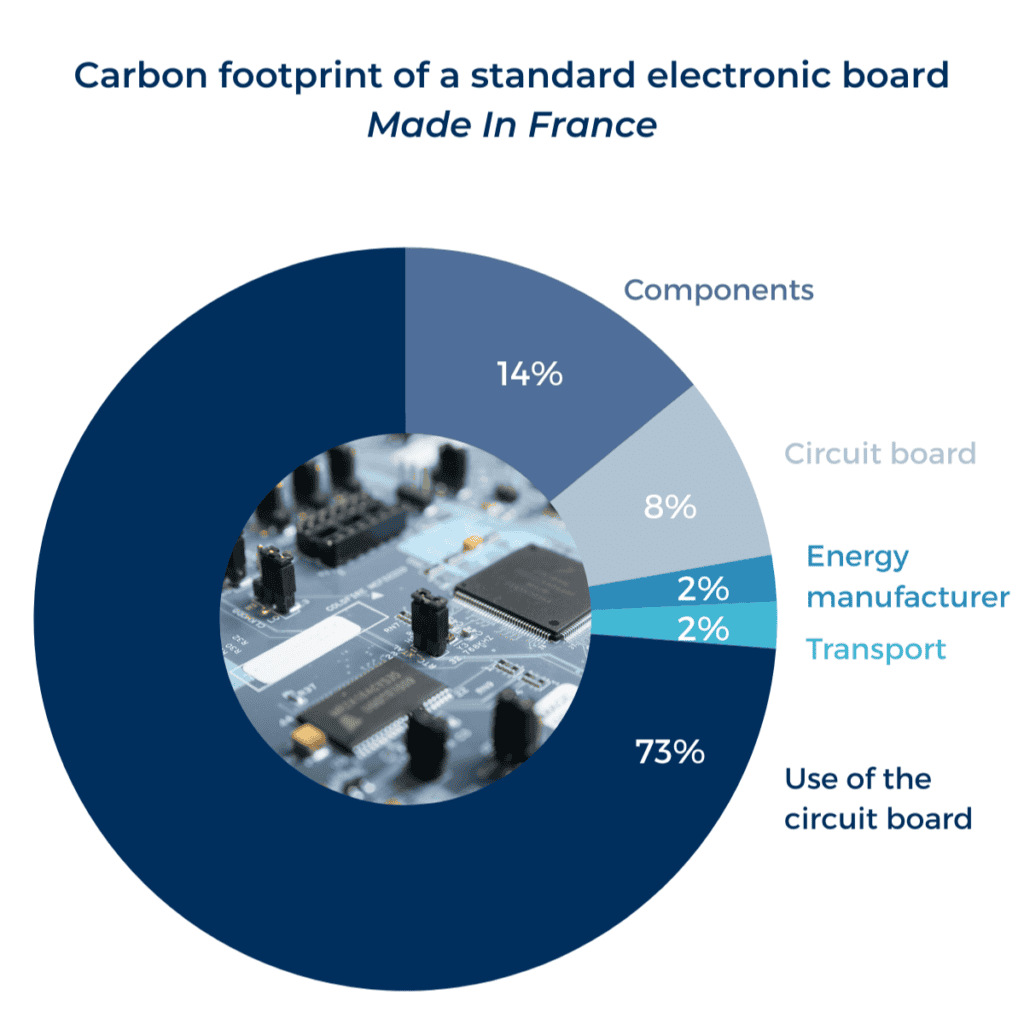

- Yet 85% of LACROIX’s carbon footprint is linked to the energy consumption of our products during their usage.

- 13% of our products’ carbon footprint is linked to the purchase of raw materials (components, PCBs, metal, plastics, etc.).

Acting on these levers enables us to cover more than 98% of the footprint. Therefore they are at the heart of our priorities.

LACROIX Eco-design approach

Our Ecodesign approach is integrated into our development process to reinforce the consideration of environmental aspects and practice of ecodesign in all our activities.

To design eco-efficient solutions, our R&D teams integrate key technologies that have proven their usefulness and sobriety, guaranteeing useful, robust and secure connected equipment.

To objectivize the ecodesign performance of our products, we use the Single Score of the PEF method (Product Environmental Footprint) launched by the European Commission.

In 2024, 71% of our new products were eco-designed.

Case study: SOFREL LogUp

The SOFREL LogUp data logger of our Environment activity illustrates our commitment to ecodesign by optimizing integrated circuits and reducing the number and surface area of printed circuit boards.

As a result, the solution’s overall environmental impact has been reduced by 74% compared with the previous model.

The 2025 objective is for 100% of our new products to be eco-designed, and to become a leader in eco-design in our markets.

Ecoconception & Life Cycle Assessment (LCA)

By measuring a product’s environmental footprint over its entire life cycle (production, use, end-of-life), LCA enables us to identify the elements/stages of the life cycle on which we should focus our eco-design efforts.

We carry out the LCAs in-house and use EIME software, the benchmark for electronic products.

100% of the new products within our Environment activity are subject to a Life Cycle Assessment (LCA).

In 2024, we conducted 6 Lifecycle Assessment, with a multi-criteria analysis (quantifying all environmental impacts) over the entire life cycle of products.

For our Electronics activity, we want to be able to provide our customers with the Product Carbon Footprint (PCF) of the circuit boards we manufacture.

Discover our Impact Report

Want to find out more?

Find out more about all our actions under the 4 pillars of our positive impact strategy.